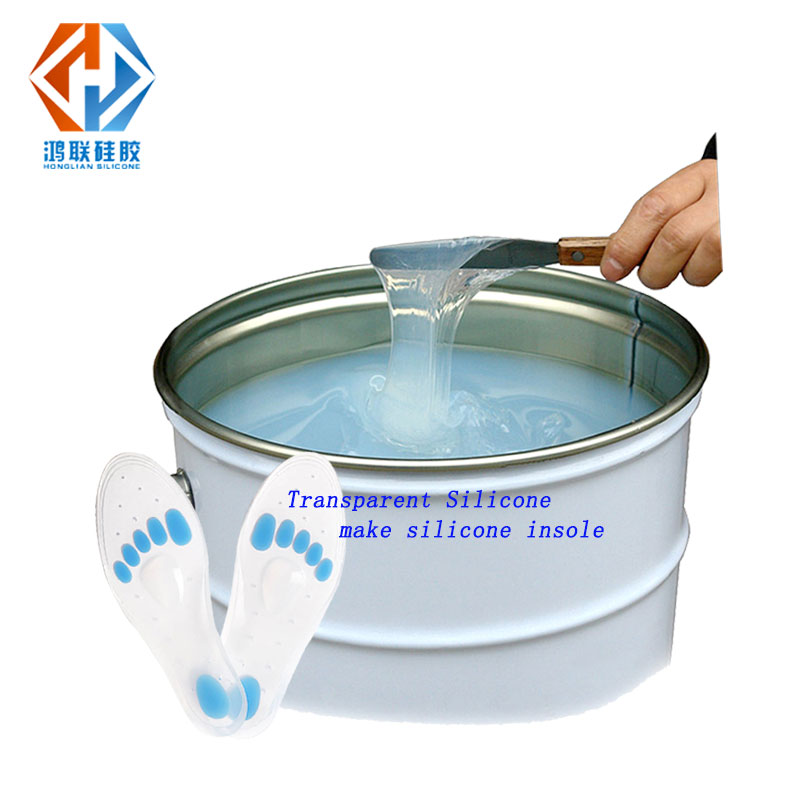

Transparent liquid silicone rubber make shoe insole HL-1600 platinum cure silicone 2 component liquid rubber

Description:

This series liquid silicone rubber as a two-component heating vulcanization platinum cure silicone rubber, part A and part B, the mixing ratio by weight or volume is 1:1 or 10:1, mainly be suitable for making molds and high quality silicone products application, through the FDA ,ROHS, SGS, LFGB testing, can cure at room temperature or fast cure dozens of minutes under heating reach 80-120 centigrade. silicone color, hardness, pot life, cure time all can customized according your need.

Application:

This series liquid silicone rubber used in high-grade casting molding products,shoe insole, toe insole, heel insole, medical equipments, silicone gasket, cake molds, candy molds, chocolate molds, sugar molds, edible cake decoration molds, butter shape molds, ice cream molds, soap molds, candle molds, resin molds, polyresin mold, polyurethane molds, craft molds, bake molds, silicone O-ring, medical appliance, food mold, and many other silicone products, etc

Parameter:

Items |

|

NO. | HL -1600 |

Appearance | transparent (custom) |

Viscosity (Pa.S) | * (custom) |

Density (g/cm^3) | 1.18 |

| Mix ratio (A:B) | 1:1 (by weight or volume) |

Hardness (shore A°) | 8±2 |

Temperature resistance (℃) | -60+350 |

Elongation (%) | 600% |

Tensile-strength (KN/m) | ≥30 |

Condition of cure | A/B component according 1:1 mix ratio by weight mix evenly, silicone can cure about 4-10hrs at room temperature, if you heating to 80-90℃ silicone can cure about 15-30mins easily |

NOTE: all silicone color, mix ratio, cured hardness, work time, cure time, packing size etc all can customize according your requests.

Silicone characteristics:

1.Food grade, non-toxic, non-smell

2.Safety touch with skin or food

3.Good anti-aging, low shrinkage

4.High or low temperature resistant range -60-350 centigrade

5.Excellent flexible, low shrinkage

6. High Duplication Times

Referance operation:

As no two applications are quite the same, a small test application to determine if performance of this material suitability for your project is recommended.

1, Measuring & Mixing:before you begin, pre-mix Part A and Part B separately. After dispensing required amounts of Parts A and B into mixing container (1A:1B by weight or by volume), mix thoroughly making sure that you scrape the sides and bottom of the mixing container several times

2, Vacuum Degassing: After mixing parts A and B, vacuum material for 2-3 minutes at vacuum box, making sure that you leave enough room in container for product expansion.

3, Pouring : brushing or injection or casting the completion of the deair bubble in addition to the silicone into the mold (before pouring, first cast in the mold detergent or mold release agent that is better demolding.)

4, Curing: to complete the above steps, the silicone to cure for 2-12 hours fully cured depends on room temperature ; if heating 80-120 centigrade, can be completely cured within a few minutes.

5, Tips: This product will not cure against surfaces containing sulfur, tin, even when sealed.If you are not sure if your clay contains sulfur, do a small compatibility test before using for an important project.

Shelf life:

Under the room temperature is 25-30 centigrade, 12 months

Packing specification: this product is made from steel drum/plastic barrels packaging, specification is 5 kg, 20 kg, 25 kg and 200 kg per drum

Storage and transportation:

should be kept sealed in ventilation, cool, dry place, away from the children's place, prevent sun direct illuminate, belongs no dangerous goods of transportation, can use express, air cargo, sea transportation, land transportation.

Sunny Guo

Dongugan hong lian organic silicon technology co.,ltd.

Tel/Fax:+86769 85075949

Mob:+86 18680616828 (wechat/whatsapp)

Skype:sunnyguo3972

Email:silicone@hongfengdg.cn

Web:www.hlsilicone.com

Store:hlglue.en.alibaba.com

【Next】:NO